The alcohol industry, historically resource-intensive, is undergoing a sustainability revolution. Leading producers are embracing carbon-neutral and zero-waste practices, reducing their environmental footprint while reaping significant business advantages.

Achieving Carbon Neutrality

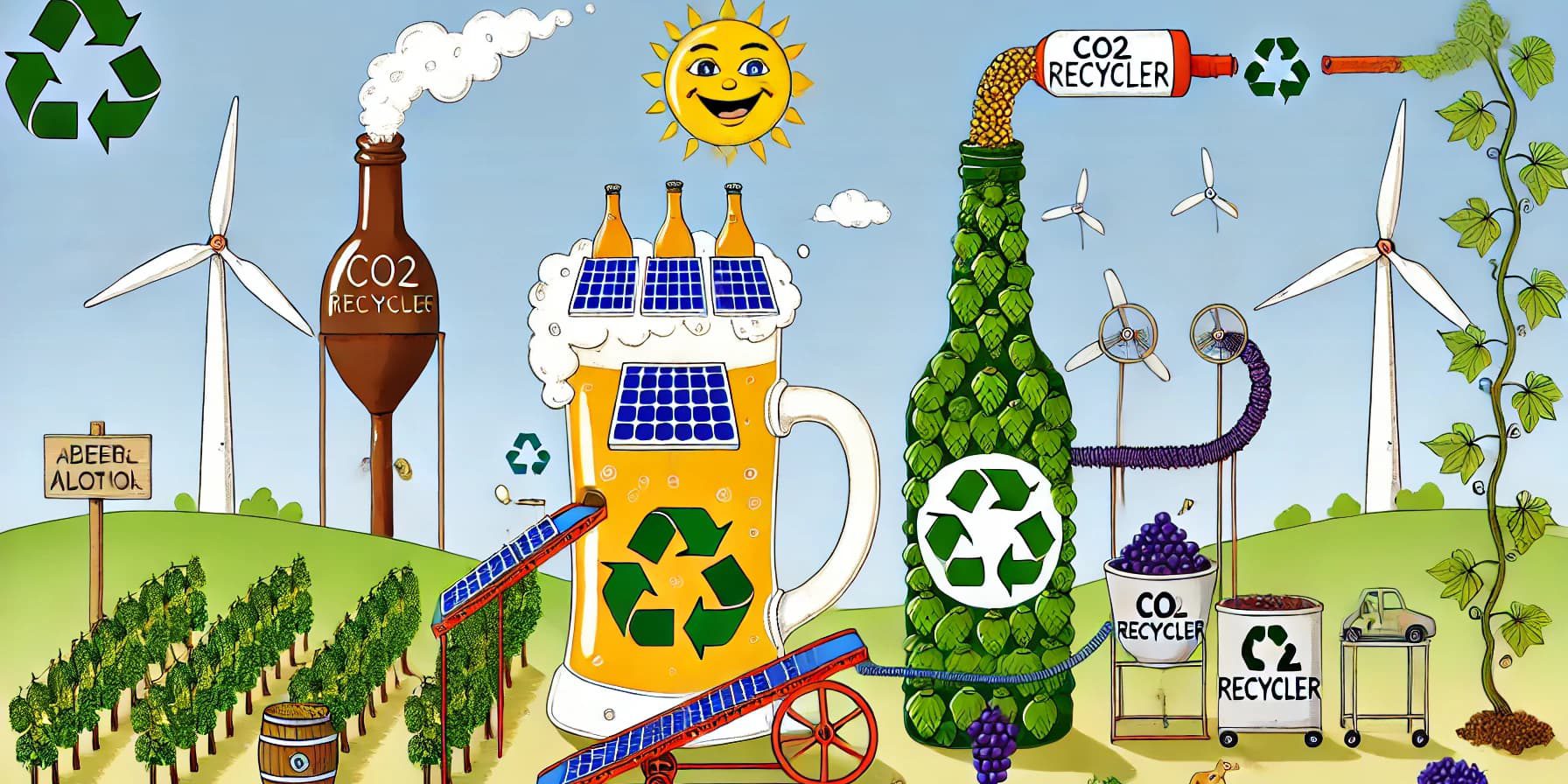

Sustainability begins with energy. Breweries and distilleries now invest in renewable sources such as solar and wind power. Coupled with energy-efficient brewing systems, these efforts significantly lower carbon emissions. Tools like Sustain.Life empower companies to measure, manage, and mitigate their environmental impact, enabling informed strategies for decarbonization.

Closing the Waste Loop

Water conservation and organic waste recycling are central to zero-waste operations. Brewers repurpose spent grain as livestock feed or bioenergy, turning byproducts into valuable resources. Packaging innovations, like biodegradable materials, further minimize waste.

CO2 Capture: A Circular Solution

Fermentation produces substantial CO2, a gas essential for beverage carbonation and preserving freshness. Forward-thinking breweries, such as Sierra Nevada, utilise CO2 recapture systems, harnessing this gas to avoid purchasing externally sourced CO2. These systems reduce emissions and insulate businesses from supply shortages—a dual win for the environment and bottom line.

Broadening Applications Across Industries

CO2 recapture, though established in brewing, holds potential for wineries and other beverage producers. Fermentation in winemaking also generates CO2, which could be reclaimed for carbonation or storage. Widespread adoption would amplify environmental benefits across sectors.

The Business Case

Adopting these practices bolsters operational efficiency, cuts costs, and aligns brands with eco-conscious consumers. Regulatory incentives and public pressure are compelling producers to act, transforming sustainability from an ethical choice into a competitive advantage.

Dunnet Bay Distillers, based in Caithness, Scotland, is a standout example of a small business embracing sustainability. Makers of Rock Rose Gin, they have incorporated solar energy, recycled organic waste for agriculture, and introduced innovative eco-friendly packaging, including recyclable gin pouches.

The company is working toward achieving net-zero carbon emissions by 2030, a goal they actively support through carbon offset projects while improving internal emissions reductions. This transition demonstrates that it’s never too late to join the sustainable movement and contribute meaningfully to environmental goals

Looking Ahead

Vinsight offers tools for businesses in the alcohol production sector to efficiently manage and track overhead costs, including electricity, carbon emissions, waste, and other operational factors. The platform’s overhead allocation features allow producers to record, analyze, and assign these expenses to various production activities. This helps businesses better understand their resource usage and environmental footprint while aligning operational decisions with sustainability goals. Such a feature supports companies aiming to measure and mitigate their carbon impact, aligning with broader trends in sustainable production.

The path to sustainable alcohol production relies on innovation. Investments in cutting-edge CO2 capture technology, renewable energy, and waste management systems promise a greener, more profitable future.

By aligning environmental stewardship with business goals, the alcohol industry can lead the charge toward a sustainable, zero-waste economy.